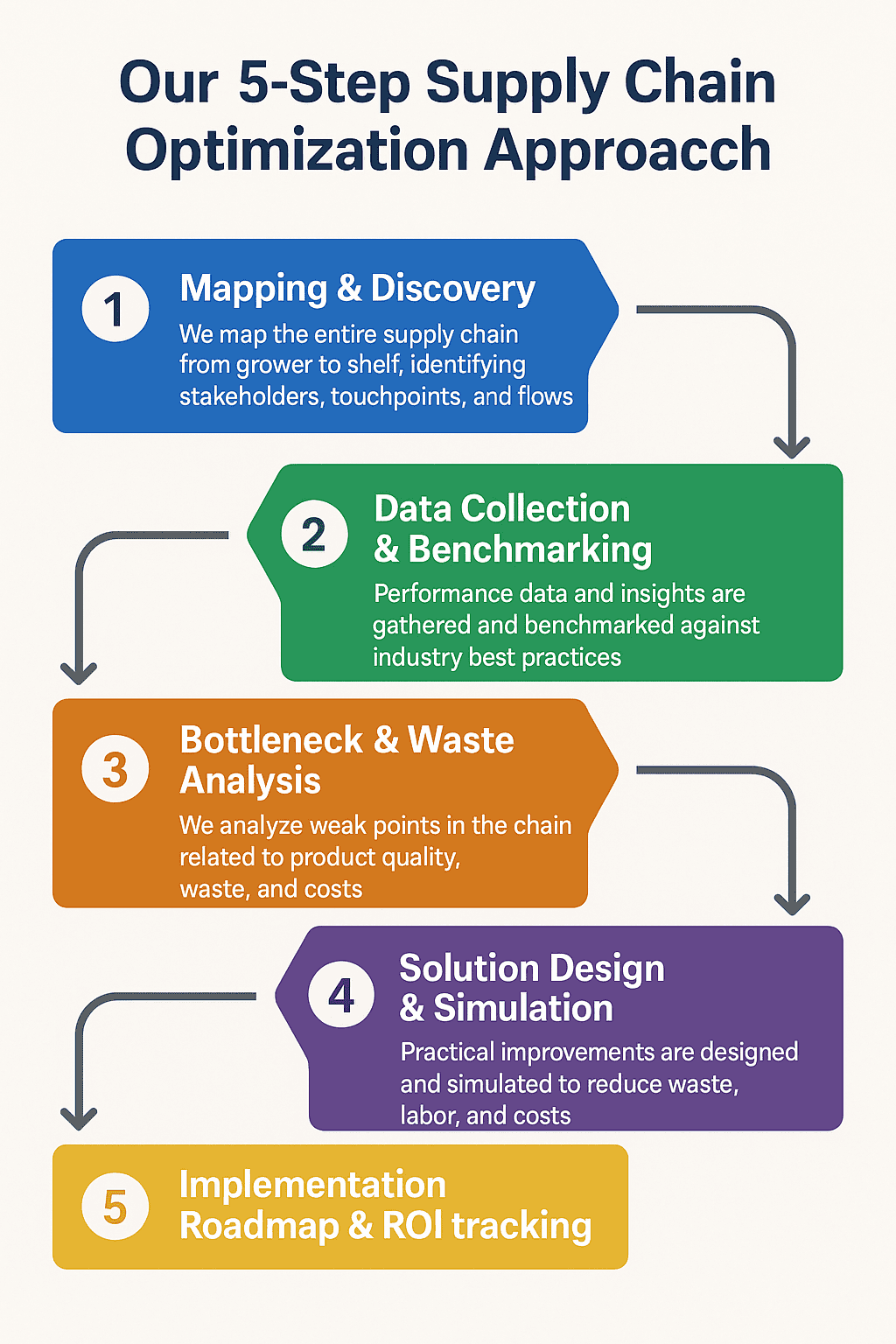

Our approach process analysis

Optimizing complex processes requires a structured and data-driven approach. Every step in the chain influences efficiency, quality, costs, and overall performance. Our 5-step framework provides a clear method to identify inefficiencies, design practical improvements, and achieve measurable results.

1. Mapping & discovery

We begin by mapping the entire supply chain journey of fresh products from grower to shelf. This includes transportation, storage, packaging, and in-store presentation. By identifying all stakeholders, touchpoints, and flows, we gain a clear overview of where potential inefficiencies may occur.

2. Data collection & benchmarking

Through on-site observations, performance data, and stakeholder interviews, we gather detailed insights into material handling, product losses, labor use, and logistics. We then benchmark these findings against best practices in the industry, highlighting gaps and opportunities.

"As a manufacturer of cleaning products, we were impressed by Elips Solutions’ structured 5-step approach. They mapped our supply chain from production to shelf, highlighted where we lost efficiency and provided practical solutions we could implement right away. By introducing smarter packaging and handling improvements, we reduced waste, saved labor time and lowered costs. The process was clear, data-driven and delivered measurable ROI within months. For us, it was not just advice, but a real partnership that made our operations more efficient and sustainable."

3. Bottleneck & waste analysis

Fresh products are highly sensitive to time, temperature, and handling. We focus on identifying weak points in the chain, such as excessive handling steps, poor packaging fit, inefficient shelf replenishment, or cold-chain interruptions. Each bottleneck is linked to its impact on product quality, waste, and cost.

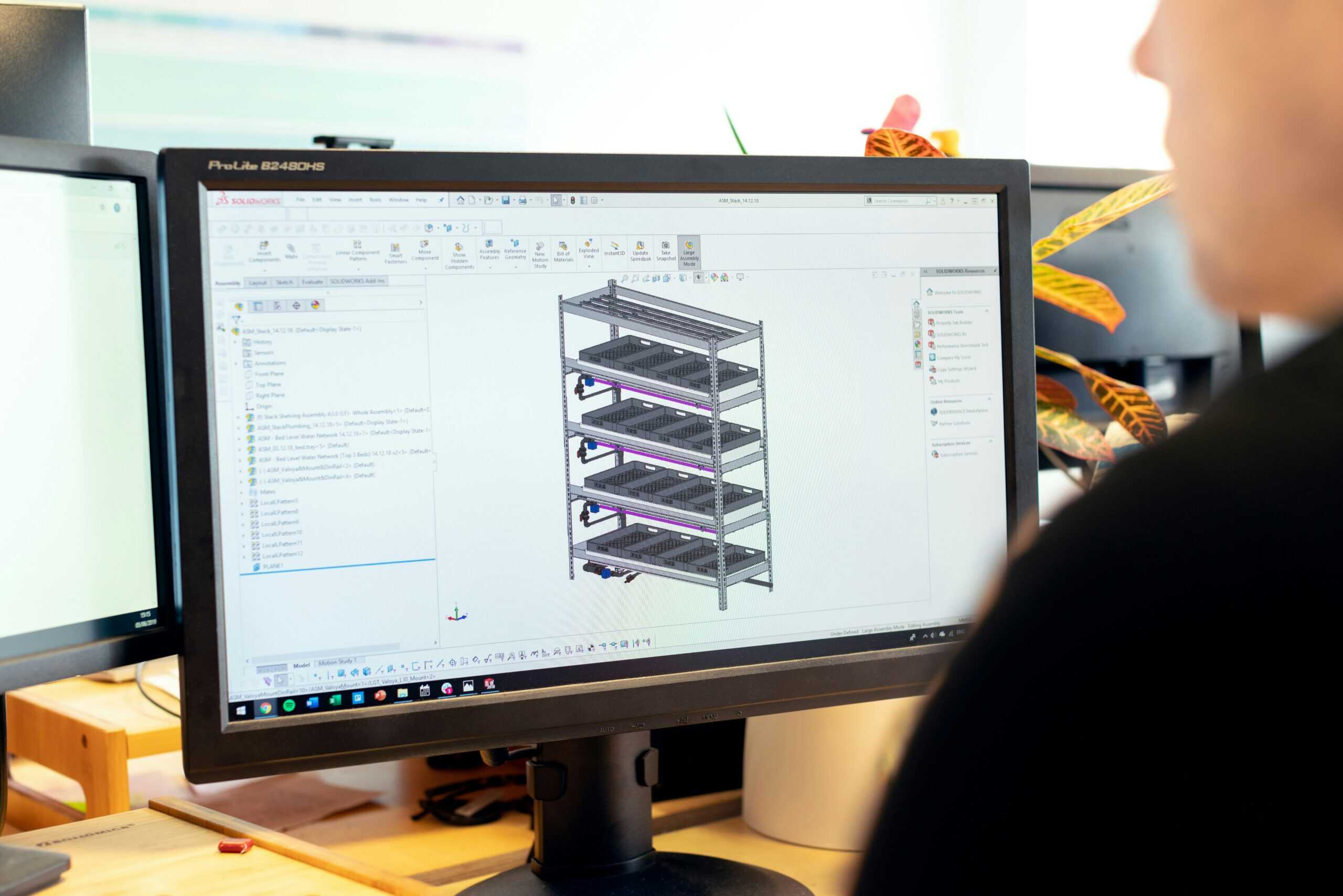

4. Solution design & simulation

Based on the analysis, we design practical improvements. These can include new packaging or crate inlays, optimized roller & push systems, improved transport solutions, or automation in material handling. We test and simulate these changes to validate their effect on reducing waste, labor, and costs while improving freshness and availability.

5. Implementation roadmap & ROI tracking

Finally, we create a clear step-by-step roadmap for implementation, including responsibilities, milestones, and measurable KPIs. We track ROI by monitoring improvements in product shelf life, reduced shrinkage, optimized labor hours, and higher sales conversion at the shelf.

At Elips Solutions, this 5-step approach ensures that fresh products are handled smarter, waste is minimized, and the supply chain operates more efficiently, from farm to fork. By combining practical expertise with innovative tools such as inlays, roller systems, and optimized packaging solutions, we help retailers and suppliers protect product quality, extend shelf life, and reduce costs. Our focus is on creating solutions that are not only efficient but also sustainable, ensuring long-term impact for both businesses and the environment. With measurable results in reduced shrinkage, improved labor efficiency, and better shopper experience, our method delivers value at every stage of the chain. Ultimately, we empower our partners to turn everyday challenges into opportunities for growth and innovation.